Biofloc technology is the latest technology for fish farming in the world. It is possible to produce more fish on less land using biofloc technology. The era has changed so much that fish farming no longer requires ponds or ditches. In modern times, due to the scarcity of land, fish farming has now entered the house.

Fish is being farmed indoors by combining specific techniques and technology. This method is called biofloc. This is very popular fish farming system at now in China, Malaysia, Vietnam, Singapore, India, Bangladesh etc.

What is a biofloc technology?

The word bio comes from the Greek bios, which means life. And flock means the sum of the gently attached cones. Reusable food is made from organic waste nutrients in the biofloc method. So naturally biofloc technology is a sustainable and environmentally friendly method of fish farming.

This method creates a thin coating of bacteria, microorganisms and algae in the pond water. Which filters the water. Nitrogen from water absorbs harmful substances. Microorganisms play two major roles in the biofloc system-

- Microorganisms maintain water quality by converting nitrogen compounds present in water into proteins.

- Biofloc technology increases the feasibility of farming by reducing the food conversion rate and food costs in fish farming.

Can fish be farmed in biofloc technology?

Different species of fish can be farmed using biofloc technology. Those who are going to use biofloc technology for the first time must first start farming with tilapia, horn and catfish. However, in other countries, tilapia and shrimp are mainly cultivated using biofloc method. The most popular of these is shrimp farming.

Benefits of fish farming in Biofloc technology

About 80% of the cost of fish farming is spent on food. In this method the beneficial bacteria in the system make the microorganic protein in the tank itself, so this method requires much less food than in other systems. The cost of cultivation decreases and the profit is higher. Beneficial bacteria prevent harmful bacteria from growing. As a result, the fish is protected from these bacterial diseases. Therefore, it is possible to protect the farm from the outbreak of disease during biofloc technology.

Since beneficial bacteria (probiotic bacteria) are used in biofloc. As a result, it is possible to provide high biosecurity to the entire system by increasing the quality of water and controlling harmful pathogens. Beneficial bacteria (probiotic bacteria) make protein using harmful ammonia and carbon supplied from outside.In this method the water quality of the tank can be controlled. Fish growth can be ensured by controlling harmful pathogens, converting fish feces and leftover food into proteins needed for fish.

In the case of fish farming, the lower the rate of food conversion rate, the higher the profit in fish farming. The food conversion rate (FCR) of this system is lower than other systems. Fish is being farmed using beneficial bacteria that exist in nature. As a result, there is no need for various chemicals and antibiotics used in biofloc fish farming in this method. So it is an environmentally friendly fish farming method.

This method makes it possible to produce many fish in small ponds or tanks. More fish can be produced using less land and less water. Which ensures maximum use of land and water. This is a simple cultivation method. Any farmer at home can easily cultivate fish in 30-40 tanks by acquiring technical skills through proper training.

Biofloc technology can be used to cultivate 20 times more fish in the same area of the pond. In this way it is possible to produce more fish using less space. Bioflake costs 30% less fish feed than pond. Biofloc has very low incidence of fish diseases.

Equipment required for biofloc technology

Cistern or tank or house, Iron cage, triple, outlet, TDS meter, pH meter, ammonia test kits, Airator, electricity, fish, feed, probiotics, etc.

Biofloc method of water management and flock making techniques

First the tank should be disinfected with bleaching powder. After that the water should be introduced by checking the quality of the selected water. If the level of iron in the water is more than 0.2 ppm, it is necessary to remove iron from the water. In order to remove iron, apply bleaching powder at the rate of 25-30 ppm per ton of water and supply air for 10-12 hours continuously.

After that apply alum at the rate of 50 ppm and provide continuous air in water for 12 more hours. After 24 hours apply 100 ppm of Calcium Carbonate (CaCO3) lime to the water to regulate the air supply. After that the water should be introduced by checking the quality of the selected water. The qualities of water to be observed at this time are given below.

- The temperature should be between 25 – 30 degrees Celsius.

- Water colors – green, light green, brown.

- The amount of dissolved oxygen should be 7-8 mg per liter.

- The pH should be between 7.5 to 8.5.

- Alkalinity should be 50 – 120 mg per liter.

- Calcium 4 – 160 mg per liter.

- Ammonia 0.01 mg per liter.

- Nitrite 0.1 – 0.2 mg per liter.

- Nitrate 0 – 3 mg per liter

- Phosphorus 0.1 – 3 mg per liter.

- Hydrogen sulfide (H2S) 0.01 mg per liter.

- TDS 14000 – 16000 mg per liter.

- Iron 0.1 – 0.2 mg per liter.

- Water clarity 25 – 35 cm.

- Water depth – 3 to 4 feet

- Floc density – 300 g / ton

- Salinity – 3 – 5 ppt.

Floc Making

Floc Making biofloc technology. Apply salt without iodine at the rate of 1000 ppm in 1 part water of 12 parts of cultivation tank. TDS should be checked after application of salt. It is better to have 1400 – 1800 ppm TDS for biofloc technology.

If the desired TDS is not obtained after salt application, In that case, it is necessary to keep the TDS at the ideal level by applying less amount of salt. Then in the first dose 5 ppm prebiotic, 50 ppm molasses, 5 ppm East, Provide oxygen in a plastic bucket and apply after 8-10 hours of culture.

From the 2nd day, 1ppm probiotic, 5 ppm chitagur, 1 ppm yeast should be cultured with 1 liter of water per ton and applied daily.

Biofloc monitoring

Keep an eye on the following observations to see if the right amount of flock has formed in the water. ever biofloc technology in Bangladesh.

- The color of the water looks green or brown.

- Tiny particles can be seen in the water.

- Testing the ammonia in the water shows that the water is ammonia free.

- The density of floc is 0.3 g per liter of water.

- After breeding, their lineage spread.

Tank making

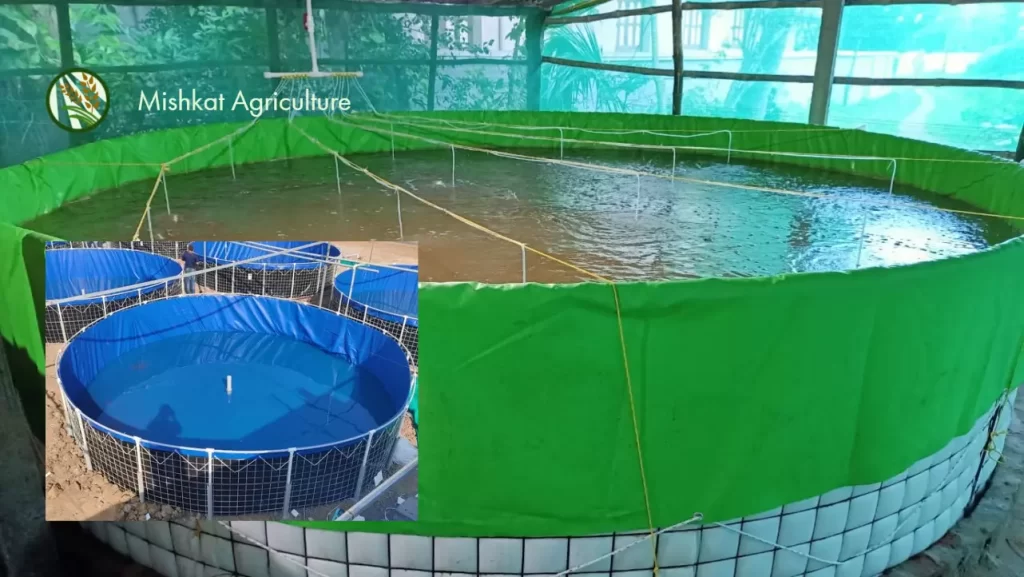

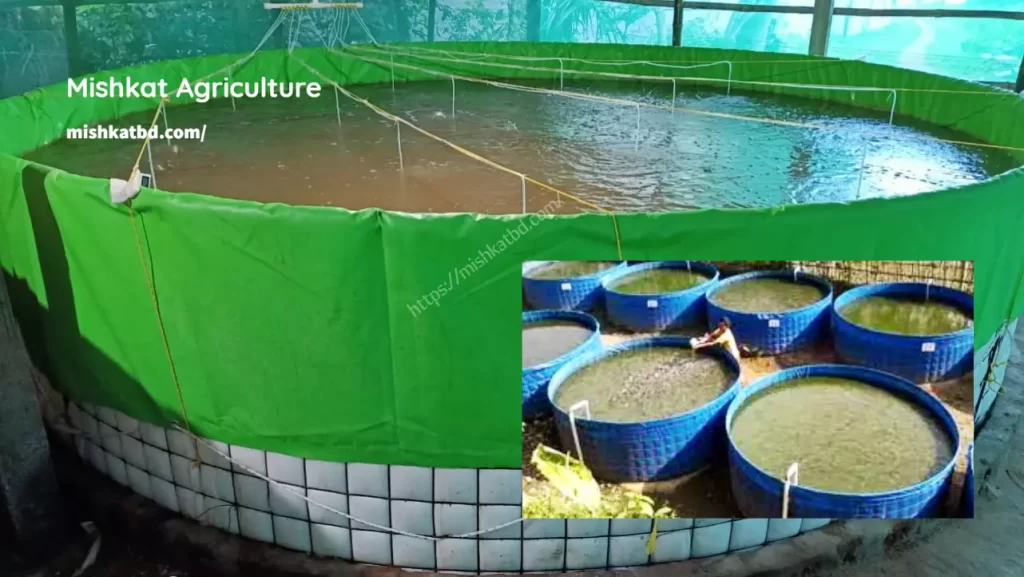

You can make both permanent and temporary tanks for biofloc. Everyone knows how to make a permanent tank with brick cement or steel sheet. Here we will learn how to make a temporary tank with triple. The round cage of the tank should be made with rods. The place where the tank will be placed should be welded equal to the circumference of the cage.

An outlet pipe for water should be placed in the exact center of the circle. Then the cage should be placed on the cast floor and buried in the ground. If the floor soil is hard and even, the floor can be prepared by spreading thick polythene evenly instead of pouring. The entire cage should then be covered with high quality tarpaulin or triple. Cover it with thick polythene and store water in it.

Let me tell you here that the tank will be 6 feet in diameter and 4.5 feet high for holding 3000 liters of water. 8 feet in diameter and 4.5 feet in height for 5,000 liters. 10 feet in diameter and 4.5 feet in height for 7500 liters. 13 feet in diameter and 4.5 feet in height for 10,000 liters. The air pump must be connected to the tank to supply oxygen to the water. For every 10,000 liters of water, 60 to 80 watt air pumps will be required along with 8 to 10 air stones.

Here are some things to keep in mind when farming fish using biofloc technology

An important component of the biofloc system is beneficial bacteria that convert waste from fish farming into protein-rich organic feeds. So you need to collect probiotic from the right source. Regular tank water quality such as ammonia, nitrate, nitrite, floc density etc. should be measured. If these are not in the right amount then necessary action has to be taken.

Daytime temperatures and nighttime temperatures fluctuate all the time, which is not conducive to flock growth. Necessary measures of temperature control have to be taken for adequate flock growth. Fish farming through biofloc, trained skilled manpower is required. If does not have technical knowledge about water quality testing, proper application of food, measurement of flock density, etc., then the farmer can be harmed at any time.

More fish are kept in the tank. So the tank has to be supplied with oxygen. And the tank will need electricity all the time to supply oxygen all the time. Otherwise, the oxygen supply to the tank will be cut off and all the fish may die at once. If oxygen is not supplied to the tank for a maximum of one hour, all the fish may die. So we have to have alternative system of electricity.

Read more- Biofloc fish farming book, Biofloc technology book pdf